SPARE PARTS

Spare Parts.jpg)

PULSING SOLENOID / DIAPHRAGM VALVE

PULSING ELECTRONIC TIMER CONTROLLER

Pulse jet control device is a main control device in a jet dust-cleaning system of a pulse bag-house. It outputs driving electromagnetic pulse valve, to control compressed air to jet duct on the filtration bag in a proper sequence, and to keep the operation resistance to clear dust within the set range, so as to guarantee the processing capability and dust-Collection efficiency of the bag house.

According to the dust-cleaning requirement of bag house, control device parameters, such as cycle interval, pulse interval and pulse width, are set, to guarantee that the operation resistance of the bag house is within the set range

.jpg)

FILTER CAGES

.jpg)

FILTER BAGS

The filter bags are the key elements which determine the dust collecting efficiency and working temperature. Renewal of bags create major cost in maintaining bag-house. So the lifetime of qualified bag can last from two years to six years under the condition of reasonable usage.

.jpg)

WALL CONNECTOR

.jpg)

DIFFERENTIAL PRESSURE GAUGE

.jpg)

AIR FLOW SENSOR

The Averaging Flow Sensor is ideal for sensing differential pressure in the inlet section of variable air volume terminal units and fan terminal units. It is use to measure the amount oh HP, LP and differential of flow. In flow system, the problems of space room are always not enough for pipe and causing flow move problems. Multi-point pressure detection hole, the average gas flow pipeline characteristic curve, and can effectively improve the current measurement of the interference problem. Flow Sensors Units can also be used to sense differential pressure at the other locations in the main or branch duct systems.

.jpg)

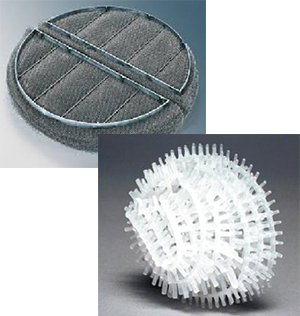

SCRUBBER PACKING MEDIA

.png)

SCRUBBER MIST ELIMINATOR

For optimal removal of a wide range of liquid droplets from gas streams